A rotary encoder is an ideal feedback device for cut-to-length applications. A fixed number of pulses is generated as the code disc rotates. These pulses can easily be correlated via scaling or simple counting to determine length of travel. When the desired number of pulses has been received by the control system, the cutting device is activated.

A rotary encoder is an ideal feedback device for cut-to-length applications. A fixed number of pulses is generated as the code disc rotates. These pulses can easily be correlated via scaling or simple counting to determine length of travel. When the desired number of pulses has been received by the control system, the cutting device is activated.

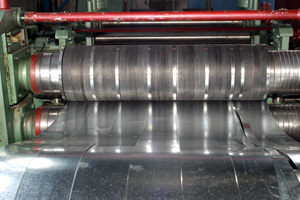

Mechanically, both shaft and through-bore encoders are good candidates for cut-to-length applications. The encoder can be applied to the drive motor used to advance material, to a head-roll shaft, a pinch-roller or to a lead screw. Additionally, an encoder and measuring wheel assembly can obtain feedback directly from the material itself or from a conveyor surface. An integrated solution such as EPC's TR1 TruTracTM simplifies encoder installation and adjustment for cut-to-length applications.

Electrically, when specifying encoder resolution for cut-to-length applications, the desired accuracy should be factored in. For example, a system with a roller that is exactly one foot in circumference, the roller would feed one foot of material for every revolution of the roller. The resolution of the encoder would directly reflect the accuracy of the cut. In this example, 96 Cycles Per Revolution would yield cuts to a 1/8" accuracy. Depending on the material, consideration should be given to static build up, including proper precautions for grounding and isolating the encoder from potential damage from static discharge.

Environmentally, proximity of the encoder to potential exposure to liquids, fine particulates and extreme temperatures will dictate specification. In applications with wash down requirements, an IP66 or IP67 seal can offer protection against moisture ingress.

Examples: