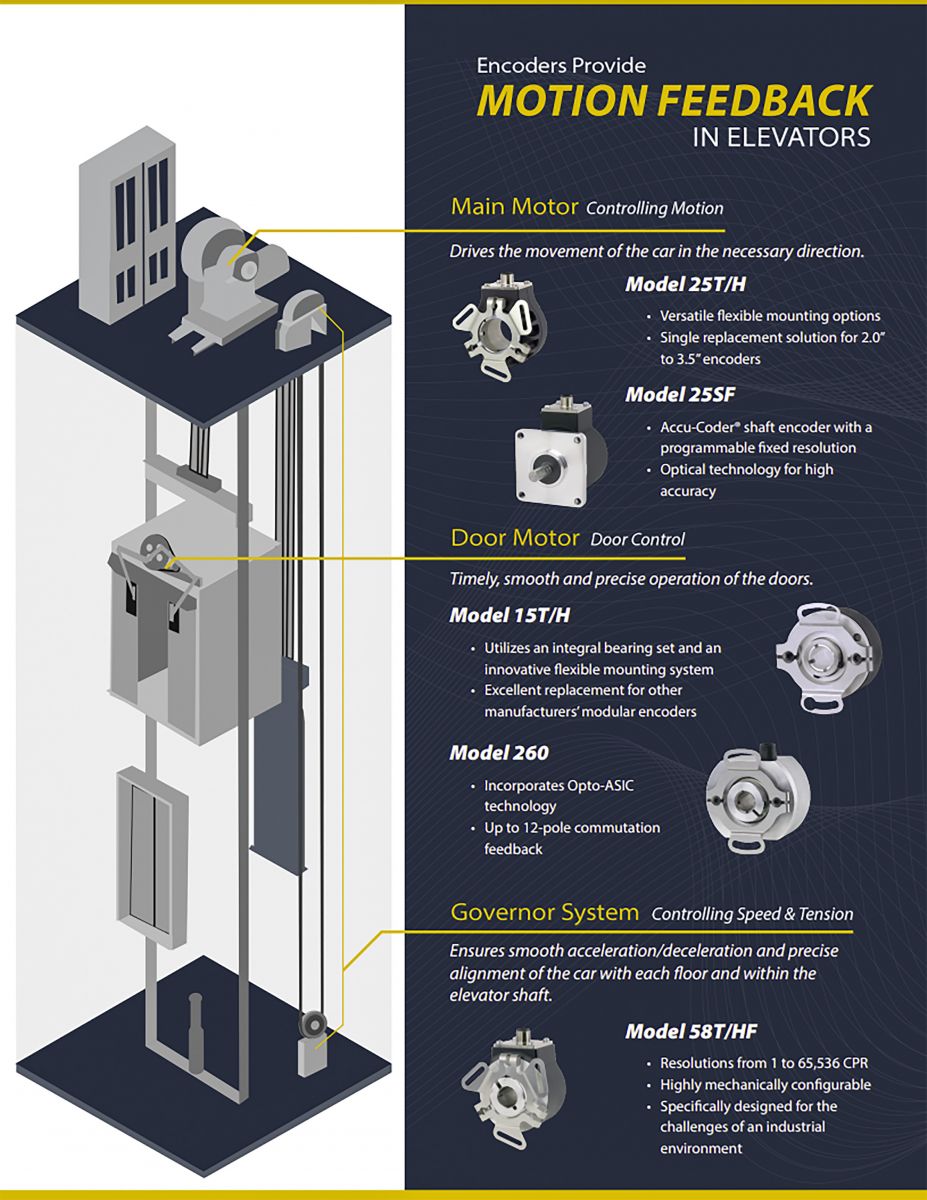

ELEVATOR ENCODERS, THE UNSUNG COMPONENT BEHIND THE SEAMLESS AND SECURE OPERATION OF ELEVATORS.

Elevators are a cornerstone of modern infrastructure, transporting millions worldwide to their destinations safely and efficiently. At the heart of this innovation lie elevator encoders, crucial devices that ensure precision, safety, and reliability in vertical transport.

Elevator encoders are sophisticated devices integrated into elevator systems, serving as the nerve center for precise control and monitoring. These powerful components convert mechanical motion into digital signals, enabling elevators to achieve accurate floor alignment, controlled speed, and safe door operations.

Encoders play a crucial role in elevator motor control by providing accurate feedback on the position, speed, and direction of the elevator car. Here's how encoders are used in elevators for motor control:

Encoders are essential components in elevator door control systems, ensuring smooth, precise, and safe operation of the doors. Here's how encoders are used for elevator door control:

.png)

In elevator systems, encoders are commonly used for shaft positioning to ensure precise alignment of the elevator car with each floor. Here's how encoders are utilized for shaft positioning:

.png)