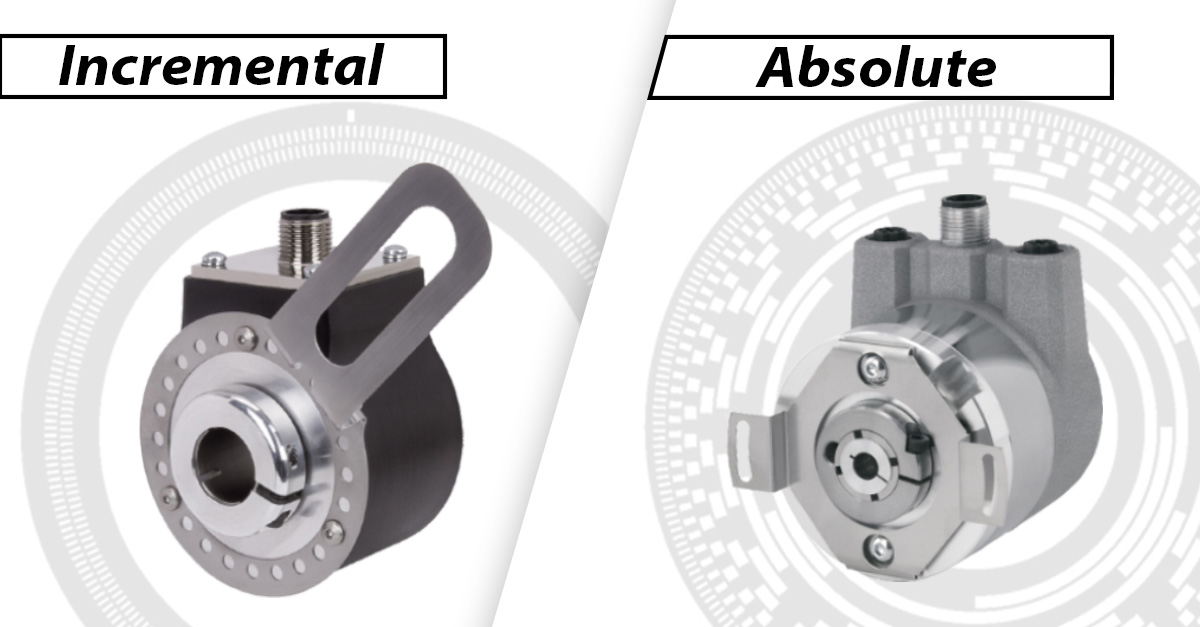

Both incremental and absolute rotary encoders are electromechanical devices that provide motion feedback about a rotating shaft.

ROTARY ENCODERS SENSE CHANGES in position of a rotating shaft, then generate signals that send speed, direction and position information to a receiving device such as a counter, drive, PLC, etc. Rotary encoders come in two basic varieties: absolute encoders report the actual position of the shaft at a specific time, while incremental encoders indicate relative changes in the shaft’s position.

Depending on the system’s feedback requirements, either type of encoder will work. But when the system powers down, absolute encoders retain their shaft position information and can pick right back up where they left off. Incremental encoders, however, must restart after power-off by establishing a starting point, or index, against which to report changes in position. This little difference becomes very important when operating conditions aren’t ideal.

The differences between absolute and incremental encoders

Both types of encoders are somewhat simple electromechanical devices, and they operate on similar principles. Each time the shaft rotates past a certain position, a sensor in the encoder registers this movement and sends either a digital signal or an electrical pulse through an output channel.

Absolute rotary encoders assign a unique code to each indicated position on the shaft, allowing them to identify the position of the shaft at any given time. For example, an absolute encoder with a resolution of 8-bits (1024), will report 1024 unique shaft position values with each rotation. Incremental encoders, on the other hand, produce an output signal, or pulse, each time the shaft passes a specified angle – the number of pulses in a given time span is enough to measure the shaft’s change in position and its speed, but does not specify the shaft’s position at any given time.

To identify the shaft’s position, absolute encoders can use magnetic or optical sensors. Either way, the encoder typically includes a magnet or marked disk connected to the shaft and a fixed-position receptor. As the shaft rotates, the disk passes output channels mounted on the receptor. More channels allow for greater resolution or more precise measurement of the shaft’s position and speed. Some absolute rotary encoders have 400 or more channels.

Incremental encoders typically have one or two channels, along with an index, or Z channel. With one channel, the encoder can count the number of rotations the shaft makes over time, but cannot determine its direction. With a second channel, typically set at 90 degrees from the first, incremental encoders can also relay directionality.

If the system loses power, an absolute encoder can resume functionality immediately upon powerup. An incremental encoder, though, cannot begin relaying usable information until the shaft has made at least one turn. For some applications, this isn’t good enough. For those cases, incremental encoders can include an additional channel, or Z channel, which serves as an index of the shaft’s position.

Which type of encoder is right for your purposes?

For some applications, like the precise orientation of radar or other sensing systems, there is no real debate: absolute rotary encoders are a must. For other purposes, including the simple measurement of shaft rotation speed, you may have an honest choice to make. The difference can often be measured in stability and cost.

Absolute encoders are uniquely able to begin operation immediately when a system is powered up. This lends them a degree of stability unavailable to incremental encoders. By the same token, their design gives absolute encoders something of a built-in failsafe. By incorporating many more channels than incremental encoders, absolute encoders benefit from an inherent redundancy: if one channel stops working for whatever reason, the system can still function normally. If the same happens to an incremental encoder, it will lose either its indexing functionality, its directional-sensing capability, or its ability to generate any useful information. Absolute encoders, in other words, can be fixed or replaced on operators’ schedules. Incremental encoders typically require immediate shutdown and replacement when they go bad.

That’s just one of the ways that incremental encoders may cost more in the long run than their absolute counterparts. The upfront cost typically favors incremental encoders by a wide margin. Absolute encoders simply contain more components to ensure higher resolution, and this means a higher up-front investment. But maintenance issues and downtime, along with the need to reinitialize incremental encoders each time the system regains power, may lead to performance losses which result in a higher overall cost option.

Wrapping it up

Absolute rotary encoders can do the job of incremental encoders and quite a bit more. On the other hand, they have a higher upfront cost, and their mechanical complexity means a higher level of care and maintenance are required. Before you commit to one solution or the other, take a look at your system’s requirements and consider the conditions under which it will operate. You may find that incremental encoders are just right for your job and that their simpler mechanical nature adds a helpful degree of reliability and confidence. On the other hand, if your system can take advantage of the benefits of absolute feedback, a wide range of options are available to you from which to choose.