Background

Alunox Advanced Tube Engineering Ltd is a specialist exhaust, manifold, and bespoke fabrication company that was founded in 2001, in Wrexham. But why this place is so special? Let us tell you why, all manifolds and exhaust systems are handmade on-site. They design bespoke units and replicate manifold systems from classic historic to motorsport vehicles (like FORMULA1), and motorbikes, they also supply the marine industry.

The owner, Leon Pearce has been developing new quieter exhaust systems for high-performance cars whilst retaining maximum power for strict noise requirements at race circuits. He has also been working on new titanium systems including using the Asnex material. This has reduced the weight by 50% (!!), therefore, increasing speed and lowering emissions for race and fast road cars!

The Problem

Machinery in a factory can encounter a wide range of problems that can disrupt production, compromise quality, and lead to operational challenges. Continuous use and friction can lead to wear and tear on moving parts, resulting in reduced efficiency and accuracy. Components such as motors, gears, belts, and bearings can wear out or break down over time, causing machinery to stop functioning properly or cause shutdowns.

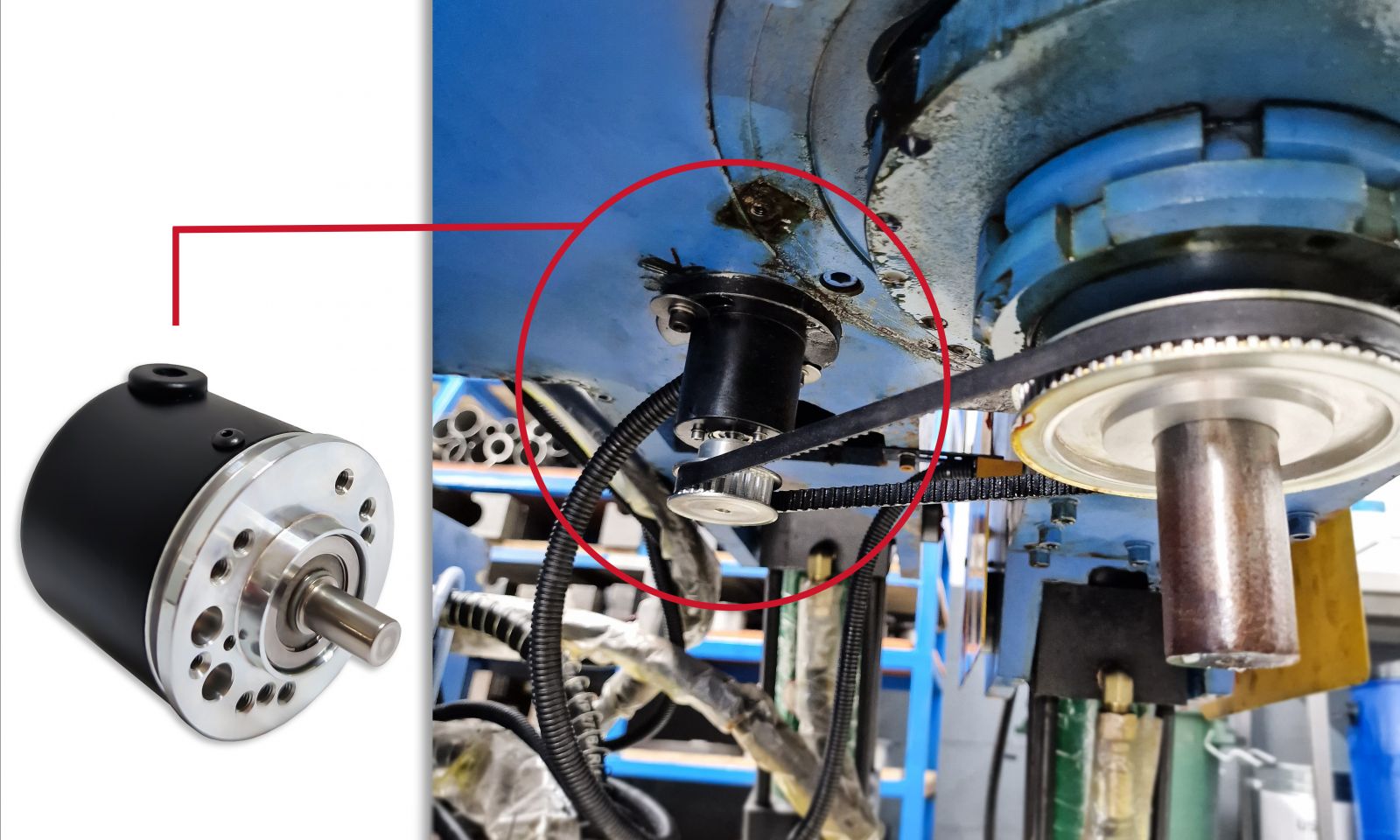

This was the case at Alunox, the constant use of the machine caused a breakdown of one of the components and a minor disruption in the production process as it was a key part of the entire production. The role of this machine is to bend metal and when the issue occurred the machine operator knew what happened, namely, the encoder did not send the signal to the system, therefore, while bending the metal the machine did not stop at the right moment. However, from the beginning, Leon knew where the problem was which allowed him to act quickly, he phoned BEPC.

.jpg)

The Solution

Whilst Leon was not using a BEPC part the cross-reference was quite straightforward and the whole process was very quick. BEPC’s solution was the Model 755 RG encoder, which Alunox company got within only 4 hrs! Yes, that's right, Leon Pearce contacted us at midday and collected his motion feedback solution 4 hrs later!

The 755 RG is ideal for applications requiring a small, high precision, high-performance encoder, with up to 30,000 PPR is designed with all-metal construction and shielded ball bearings, it will provide years of trouble-free use.

Find Out More

Do you have a question about which encoder is right for your application? When you contact BEPC, you talk to engineers and encoder experts who can answer your toughest encoder questions. You’ll get answers that make sense for your application.

With our industry-leading three-year warranty, if something does go wrong, we’ve got you covered.

Contact BEPC to find the right encoder for your application.